- info@roypath.co.za

- 072 267 8390

- Mon - Fri : 9:00 am - 5:00 pm

Welcome to Roypath

We have a collection of knife gate valves for mining and coal-fired power plant slurry applications. Aware of problems with other commercial valves, we were able to identify our new valves from reliable suppliers, ensuring that we eliminated the problem areas and incorporated all the innovations asked for by our customer

About Us

Roypath is a scientific and technological enterprise integrating scientific research and development, production, sales and service. It is a professional supplier of knife gate valves and power station valves in South Africa. One, the products mainly include one-way knife gate valves, two-way knife gate valves, slurry valves, penetrating knife gate valves, ore slurry valves, channel gates, power station gate valves, power station stop valves, power station check valves, etc.

The product structure is advanced and the performance is far beyond Domestic similar products are widely used in industries such as environmental protection, sewage treatment, paper making, mining, powder transportation, etc.

The company always regards product quality management as the first pursuit goal, and introduces foreign advanced equipment, technology, and technical personnel. The quality of its products is trusted and praised by customers. Reasonable prices, welcome new and old customers to call or come to contact us, negotiate business and trade, sincere cooperation and common development!

WHAT WE OFFER

Roypath has created a unique line of slurry valves specifically designed to provide excellent reliable service in severe applications found in matrix, in-plant beneficiation, and tailings for mining, as well as, limestone slurry, bottom ash-handling, and water isolation in Coal-fired power plants. A large inventory of our quality series 80, 120, and 150 valves are all on hand and ready for immediate service.

- Knife Gates for flow diversion and shutoff service, available from 2” to 54” ID

- Butterfly for Flow control and isolation, available from 2” to 96” ID

- Pinch for flow modulation, especially good for mining circuits, Available up to 24” ID

- Couple these with our state-of-the-art actuation, positioners, and controls, for easy open or close, Townley is your one-stop valve manufacturer for quick-turn response to your needs.

Knife Gate Valves

We have been offering knife gate valves for mining and coal-fired power plant slurry applications for close to a decade. Aware of problems with other commercial valves, we were able to identify and offer valves from a clean sheet of paper, ensuring that we eliminated the problem areas and incorporated all the innovations asked for by our customers.

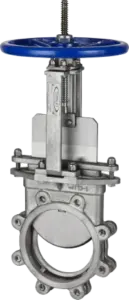

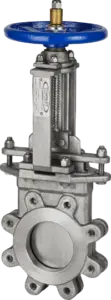

Series 80 Stainless Steel Knife Gate Valves

The Series 80 Stainless Steel Knife Gate valves are designed to deal with chemicals and high temperatures. When corrosion is accruing in your application these valves will work great. We currently offer two different stainless steel valves which serve two different types of applications. The main difference between the two valves is the rubber seat that is bonded to the SSRS valve.

Series 80 Stainless Steel Knife Gate Valves

The Series 80 Stainless Steel Knife Gate valves are designed to deal with chemicals and high temperatures. When corrosion is accruing in your application these valves will work great. We currently offer two different stainless steel valves which serve two different types of applications. The main difference between the two valves is the rubber seat that is bonded to the SSRS valve.

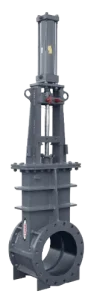

Series 150 Knife Gate Valve

The Series 150 Knife Gate Valve was fabricated with a bi-directional valve in response to customers needing a robust valve for coarse solids and tailing service in mining. These valves have found use in abrasive bottom ash discharge circuits in coal-fired power plants.

The CAD/CAM designed and CNC plasma-cut components are robot welded and pressure tested to ensure a long reliable life. The cast stainless steel double taper blade ensures a positive open and closes every cycle.

Why Choose Us:

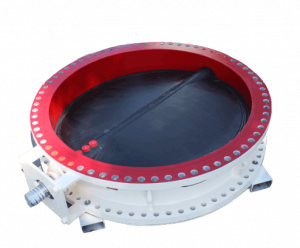

Series 120 Butterfly Valve

Designed for handling high volume solution flow, the Townley bi-directional Series 120 Butterfly Valve is an excellent choice for throttling or isolation service. This high-performance butterfly valve aligns to the center of the pipe perpendicular to the flow. Depending on the application the valve body can be lined with urethane or rubber for a bubble-tight seal.

Designed for handling high volume solution flow, the Townley bi-directional Series 120 Butterfly Valve is an excellent choice for throttling or isolation service. This high-performance butterfly valve aligns to the center of the pipe perpendicular to the flow. Depending on the application the valve body can be lined with urethane or rubber for a bubble-tight seal.

TM-3 & TM-4 General Service Butterfly Valves

Why you should use these Butterfly Valves:

Why you should use these Butterfly Valves:

- Cost-effective ductile iron body

- Available with an optional lockout feature

- New generation, cartridge-style, metal-reinforced EPDM rubber seat will not blow or peel out due to high pressure or velocity

- Precision machined disc is available in either cast 316 stainless steel or ductile iron/nickel plated

- The shaft is 410 stainless steel

- PTFE bushings provide consistently smooth operations

- Available in wafer style (TM-3) or lug style (TM-4) to suit your operating needs

- A variety of operator configurations are also available, including Spring lever with notch plate, manual gear with handwheel, pneumatic rack & pinion, electric, or hydraulic

How We Roll

We continue to meet and exceed the goals for our customers by creating unique elastomers and cast metal alloys to match the wear requirements. Our technical teams study each wear situation to ensure the best material application.